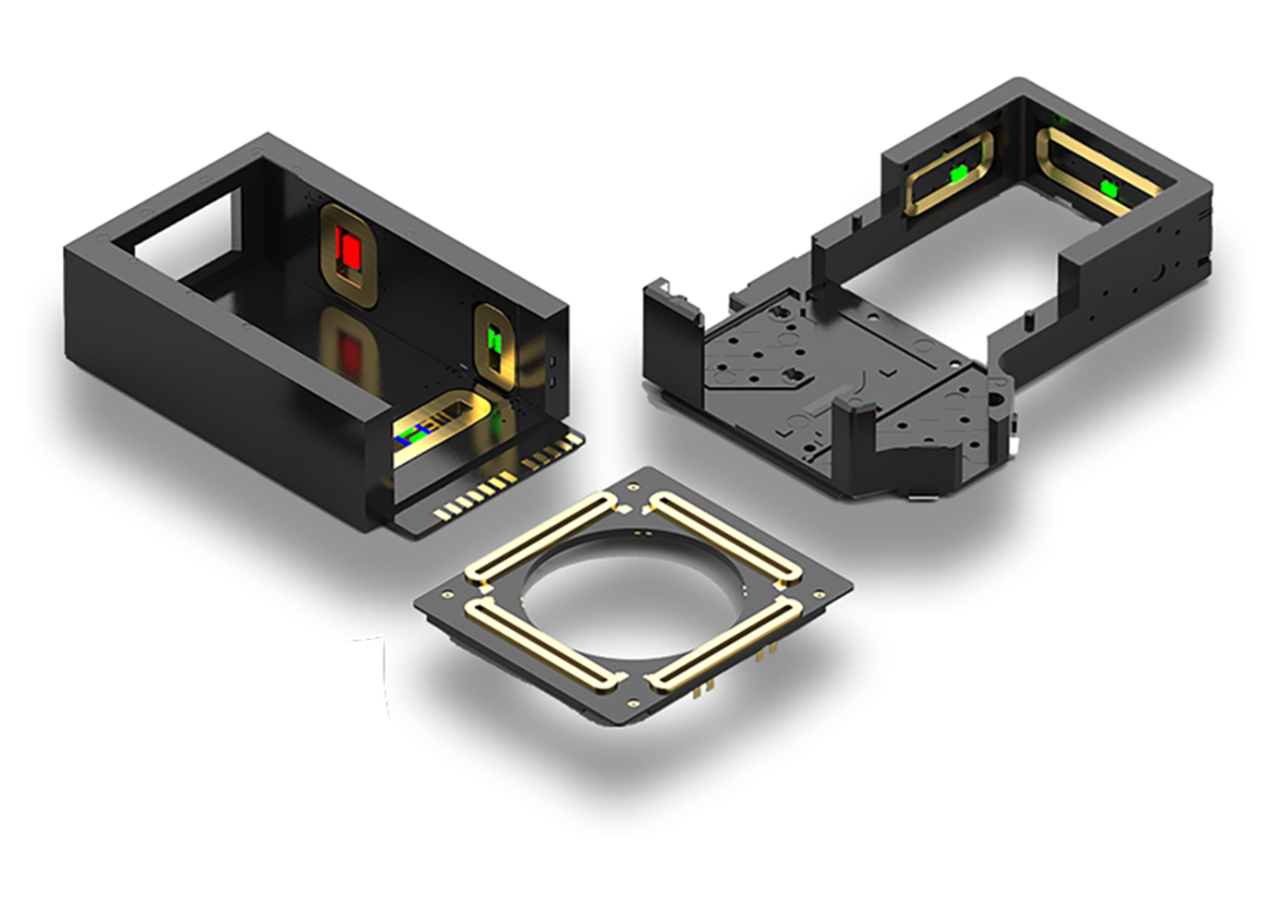

CMI Gen I

-

100% online electrical measurement ensures the product qualification rate.

100% online electrical measurement ensures the product qualification rate.

-

Integrates processes such as stamping, bending, forming, and SMT into a single product.

Integrates processes such as stamping, bending, forming, and SMT into a single product.

-

Yunzhong's fully automated production line simplifies the assembly process of motors, from terminals to product completion.

Yunzhong's fully automated production line simplifies the assembly process of motors, from terminals to product completion.

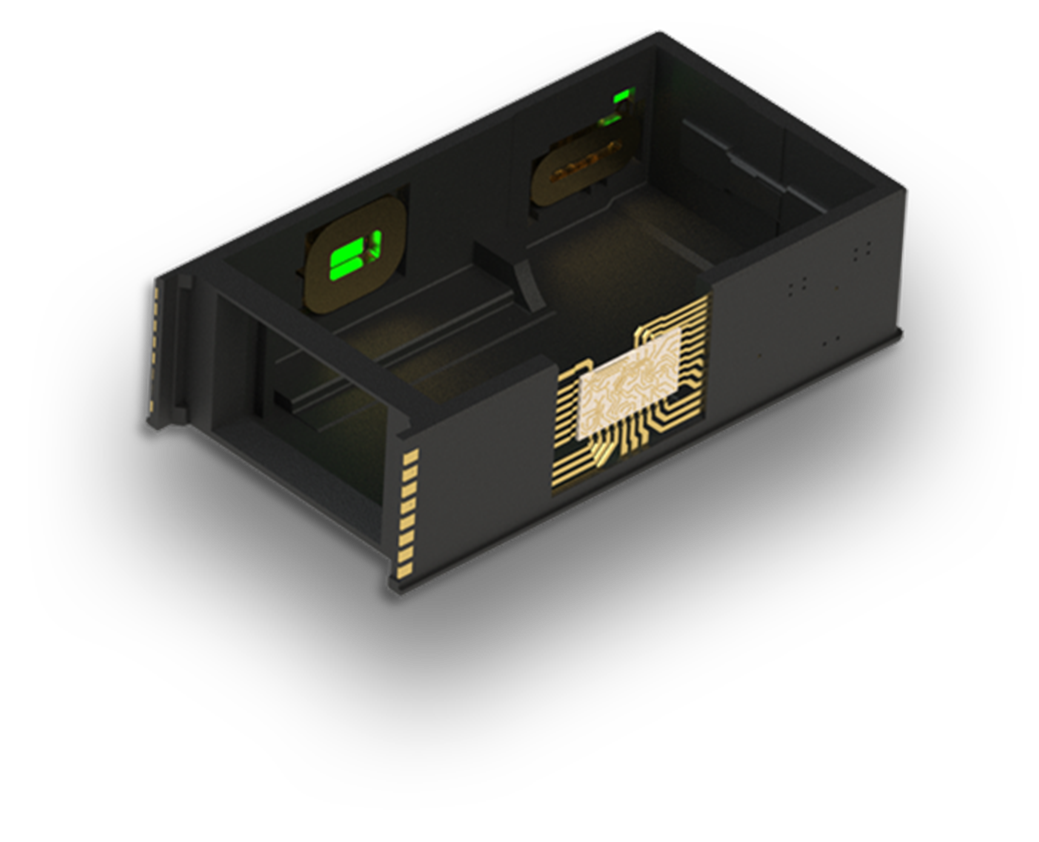

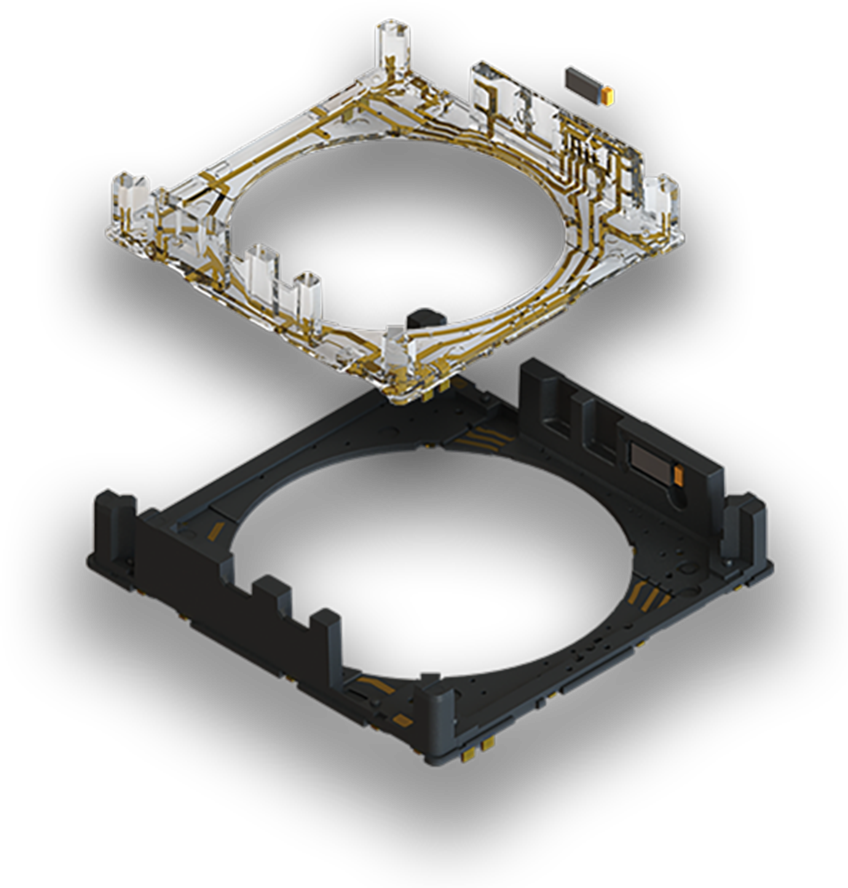

CMI Gen II

-

3D stereoscopic circuit +3D stereoscopic SMT assembly.

-

The secondary injection molding process has solved the complex product structure.

-

Significantly enhance the reliability of the product, greatly simplify the assembly process of the motor, and reduce customer costs.

-

From terminals to product completion, Yunzhong's fully automated production line, with 100% online electrical testing, ensures the product qualification rate.

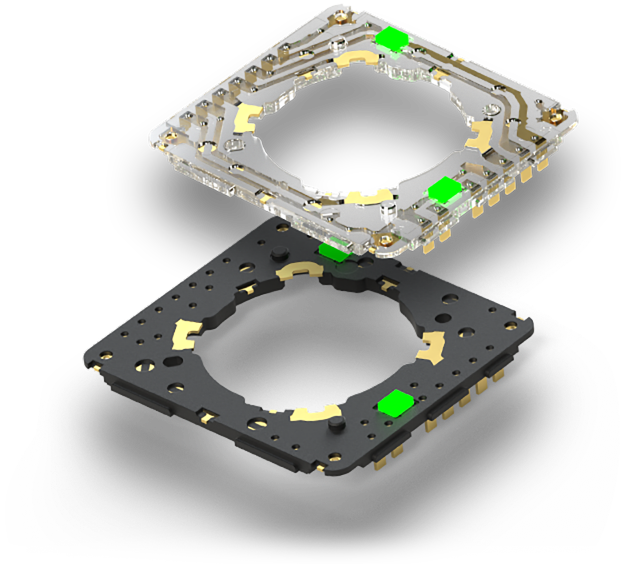

CMI Gen III

-

The coil process can save the space of the product.

The coil process can save the space of the product.

-

The secondary injection molding process has solved the complex product structure.

The secondary injection molding process has solved the complex product structure.

-

3D stereoscopic circuit +3D stereoscopic SMT patch + hollow coil attachment, welding.

3D stereoscopic circuit +3D stereoscopic SMT patch + hollow coil attachment, welding.

-

By eliminating FP-Coil and replacing it with coil technology, the same space can enhance the magnetic field thrust.

By eliminating FP-Coil and replacing it with coil technology, the same space can enhance the magnetic field thrust.

-

From terminals to product completion, Yunzhong's fully automated production line, with 100% online electrical testing, ensures the product qualification rate.

-

Significantly enhance the reliability of the product, greatly simplify the assembly process of the motor, and reduce customer costs.

CMI Gen Ⅳ

-

The FP-COIL process was cancelled and replaced by the coil process, which increased the magnetic field thrust in the same space.

-

By adopting ceramic substrate circuits and stamped terminal circuits, complex and dense circuit requirements can be addressed.

-

Hard board surface mount assembly can significantly enhance the positional and dimensional stability of components and improve product performance.

-

The manufacturing technology of the product has been enhanced through 3D stereoscopic circuits, 3D stereoscopic SMT mounting and hollow coil mounting and soldering.

100% online electrical measurement ensures the product qualification rate.

100% online electrical measurement ensures the product qualification rate.

Integrates processes such as stamping, bending, forming, and SMT into a single product.

Integrates processes such as stamping, bending, forming, and SMT into a single product.

Yunzhong's fully automated production line simplifies the assembly process of motors, from terminals to product completion.

Yunzhong's fully automated production line simplifies the assembly process of motors, from terminals to product completion.

The coil process can save the space of the product.

The coil process can save the space of the product.

The secondary injection molding process has solved the complex product structure.

The secondary injection molding process has solved the complex product structure.

3D stereoscopic circuit +3D stereoscopic SMT patch + hollow coil attachment, welding.

3D stereoscopic circuit +3D stereoscopic SMT patch + hollow coil attachment, welding.

By eliminating FP-Coil and replacing it with coil technology, the same space can enhance the magnetic field thrust.

By eliminating FP-Coil and replacing it with coil technology, the same space can enhance the magnetic field thrust.