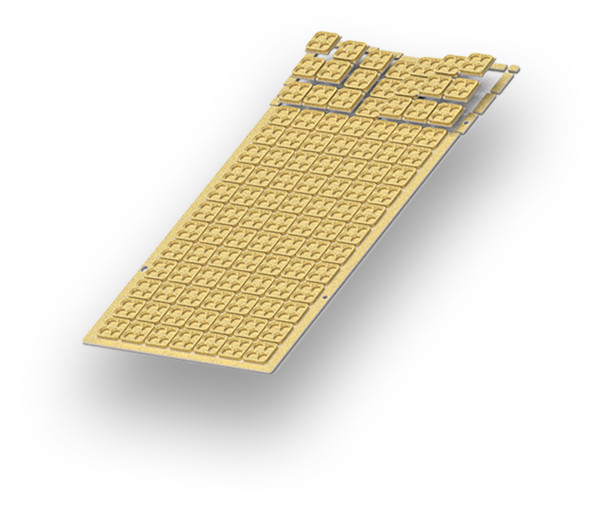

LED Ceramic Substrate

3.5mm×3.5mm×1.46mm

Deep ultraviolet LED packaging is used for three-dimensional ceramic circuit boards, sterilization and disinfection, food processing and preservation, ultraviolet detection and communication.

-

It has a very high air tightness. The bonding strength between the metal dam body and the ceramic substrate is high, which can meet the requirements of airtight packaging of electronic devices.

-

At the same time, it takes advantage of the benefits of ceramic materials and their high thermal conductivity. Secondly, it features high graphic accuracy and wiring direct imaging technology,which can precisely control the size of the pattern and the expansion and contraction of the product.

-

The manufacturing process is independently controllable and can be completed entirely within the company.

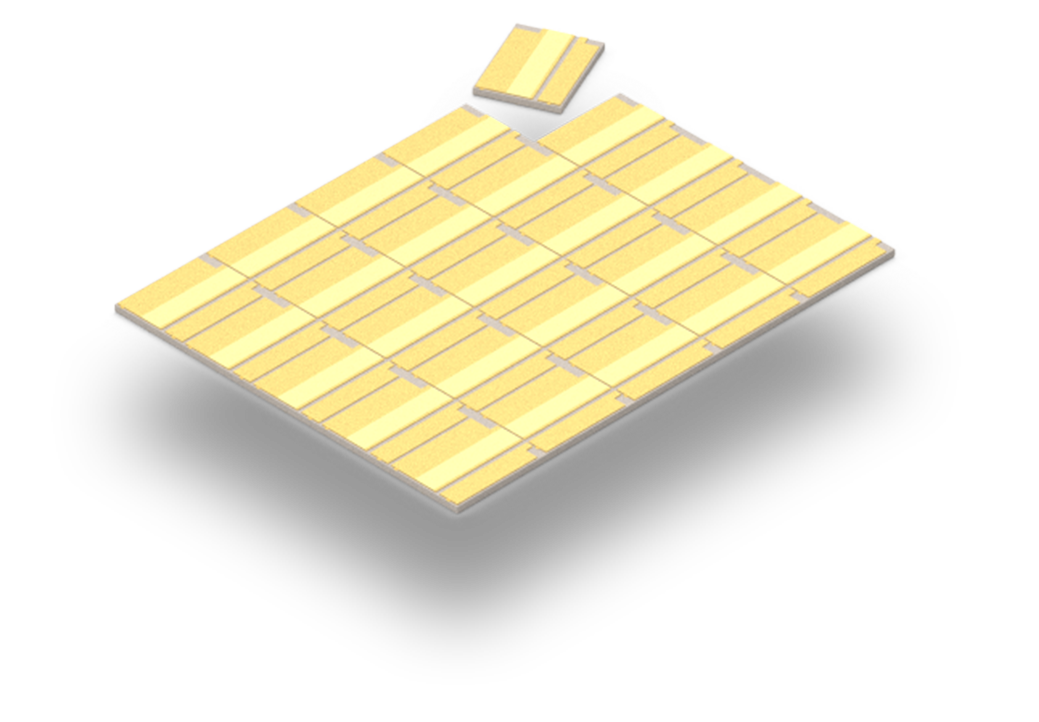

Laser Heat Sink

-

It can meet the high-temperature usage requirements of power devices and has good thermal stability.

It can meet the high-temperature usage requirements of power devices and has good thermal stability.

-

With mature prefabricated gold and tin technology, it can meet the demands of customers for chip common product bonding applications.

With mature prefabricated gold and tin technology, it can meet the demands of customers for chip common product bonding applications.

-

It has good insulation performance. Secondly, it adopts ceramic materials with high thermal conductivity such as aluminum nitride, aluminum oxide, beryllium oxide and silicon carbide, which makes it have a very high heat dissipation efficiency.

It has good insulation performance. Secondly, it adopts ceramic materials with high thermal conductivity such as aluminum nitride, aluminum oxide, beryllium oxide and silicon carbide, which makes it have a very high heat dissipation efficiency.

Ceramic heat sinks for semiconductor lasers,

laser processing, and laser welding.

laser processing, and laser welding.

5.75mm×4.5mm×0.5mm

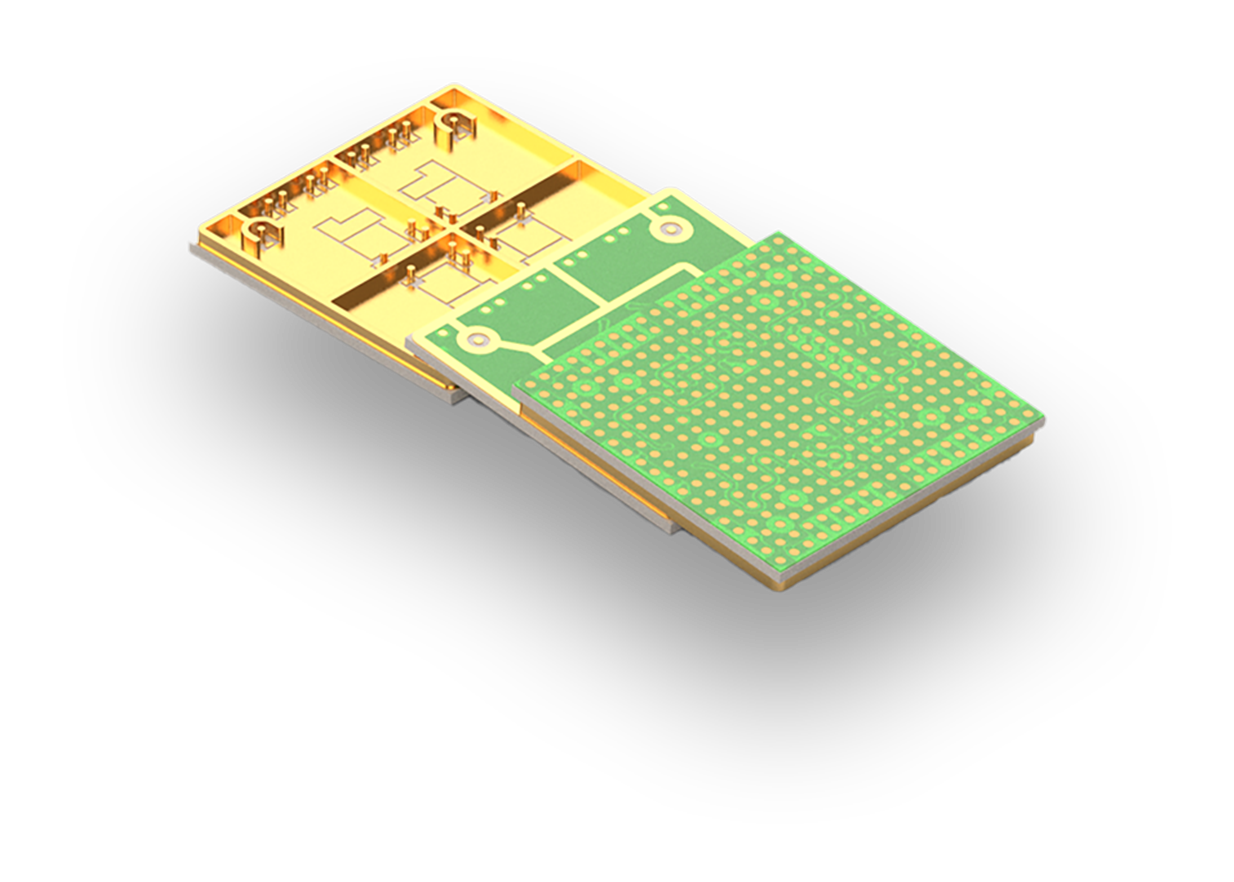

3D-MICP Airborne

Package for Missile-borne Active Phased

Array Radar T/R Modules.

Adopts an advanced 3D System-in-Package (SiR) inter

connection solution, integrating multiple vertical interconnection technologies.

connection solution, integrating multiple vertical interconnection technologies.

In high-frequency signal transmission, the signal attenuation is reduced by 40% compared with traditional solutions, meeting the extremely high requirements for high-frequency signal transmission in radar detection.

Excellent thermal conductivity and material selection enable rapid heat dissipation inside the package, reducing the junction temperature by 20℃ and effectively improving the stability and service life of the device.

Under different temperature and mechanical stress conditions, the interconnection structure can maintain stable electrical performance. Meanwhile, the product's vibration and impact resistance are significantly enhanced, with the failure rate reduced to 1/5 of that of traditional solutions.